Product Series

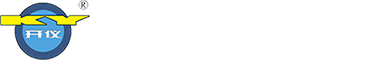

The intelligent converter is fully functional, with multiple flow displays, bidirectional measurement, air tube detection and slurry measurement, automatic process diagnosis, and multiple outputs (single current, dual pulse, dual alarm, RS232/485, Hart bus)

The intelligent converter is fully functional, with multiple flow displays, bidirectional measurement, air tube detection and slurry measurement, automatic process diagnosis, and multiple outputs (single current, single pulse, dual alarm, RS232/485, Modbus, Profibus, Hart communication, 4G/NB).

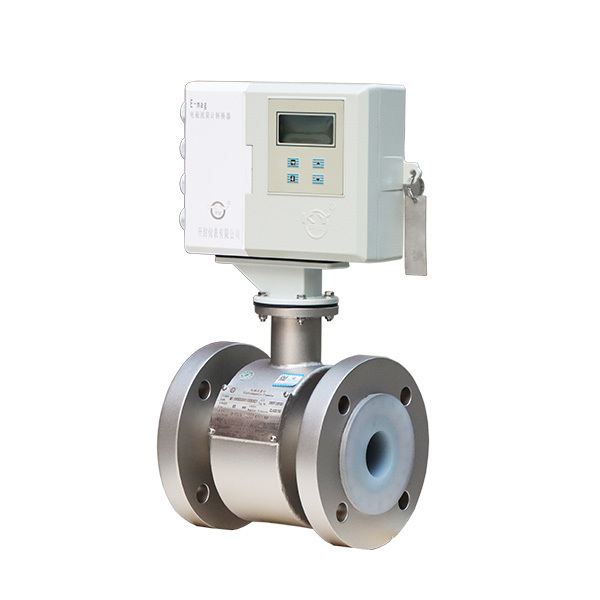

The MF/WD electromagnetic flowmeter is powered by a 3.6V lithium battery pack, and can also be provided with dual power supply according to site requirements, i.e., 220V + 3.6V lithium battery or 24V + 3.6V lithium battery (its matching converter is an IP68 integrated type). The standard lithium battery can work continuously for more than 3 years. If a high-capacity lithium battery pack is used, the continuous working time will be longer.

The intelligent converter is fully functional, with multiple flow displays, bidirectional measurement, air tube detection and slurry measurement, automatic process diagnosis, and multiple outputs (single current, dual pulse, dual alarm, RS232, HART).

The MF/H heating type electromagnetic flow meter is an inductive instrument for measuring the volumetric heat of conductive fluids. Heat measurement is calculated by multiplying the heat melt values at the inlet and outlet by the flow rate; the flow measurement part is based on Faraday's law of electromagnetic induction.

The intelligent converter is fully functional, with multiple flow displays, bidirectional measurement, air tube detection, automatic process diagnosis, and multiple outputs (dual current, dual pulse, dual alarm, RS485 (Modbus-RTU protocol), expandable to Profibus, Hart, 4G/NB, etc.)

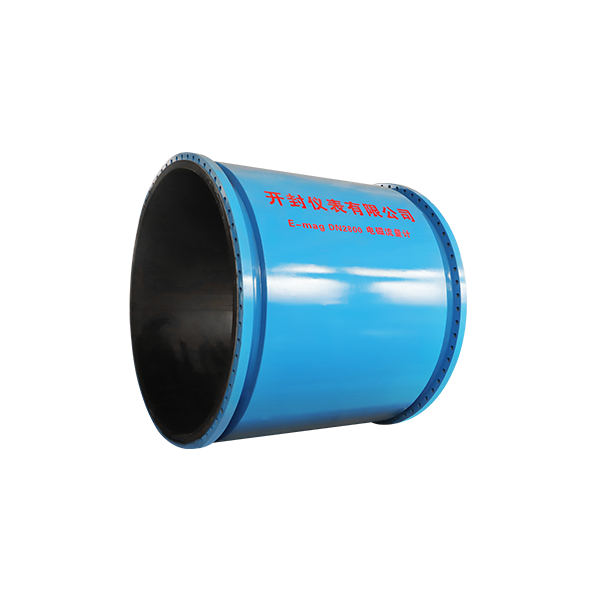

The FMI insertion electromagnetic flow meter is used to measure the volumetric flow rate of conductive liquids with minimal corrosion in closed pipes. Its excellent price-performance ratio makes it widely used in the field of large-diameter flow meters.

Applicable Medium: Suitable for most single-phase liquids (less than 5% particles or bubbles)

On-site pipeline location and opening, pressure-bearing insertion installation, pipeline material stainless steel, carbon steel, PVC, PPR, cement, suitable for working conditions that require a certain degree of measurement accuracy and stability but cannot be installed in sections.

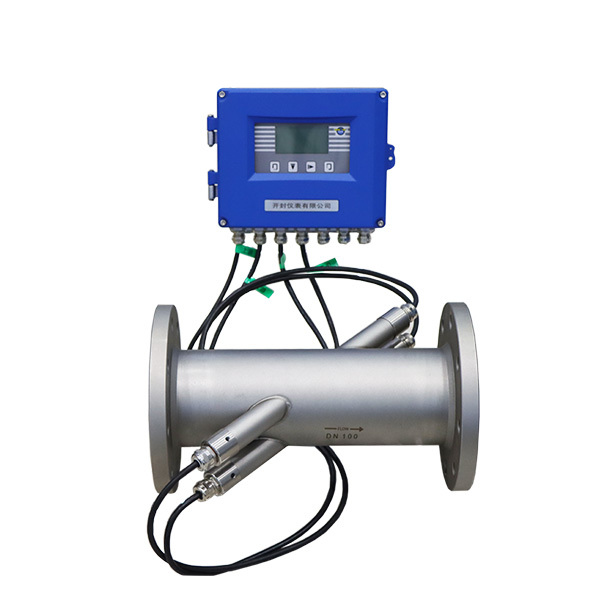

Externally attached to the pipe wall for convenient installation. Pipe materials include stainless steel, carbon steel, PVC, PPR, and cement. Suitable for high-pressure applications and special conditions where on-site pipes cannot be altered.

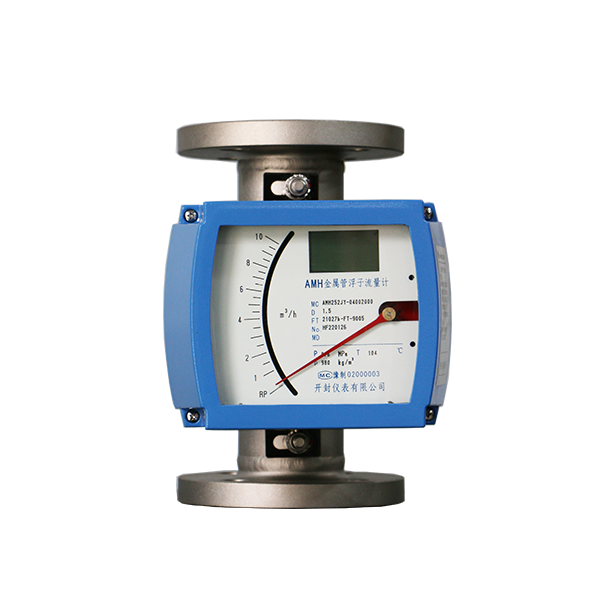

Intelligent conversion module, multiple output methods, on-site indication, 4~20mA DC electrical signal output, LCD display of total accumulation. Diverse output signals: switch signal output, HART protocol communication, FF communication, PROFIBUS PA communication signal.

Air damping device, ensuring stable measurement of low-pressure or fluctuating media; insulation or heating jacket; low-pressure loss design