Have you observed the eight common reasons for errors in electromagnetic flow meters?

2019-09-25

Regarding electromagnetic flowmeters, everyone should be familiar with them. However, what seems like a simple device, with a head and a loop, actually contains many secrets and often encounters problems. Once issues arise, it can be quite troublesome, right? Today, we will analyze how to handle problems based on on-site examples.

A 1 The liquid to be measured contains bubbles.

This is considered a common phenomenon, caused by external air intake or internal liquid dissolution. However, the electromagnetic flowmeter cannot distinguish between liquid and bubbles, so measuring them together will result in errors.

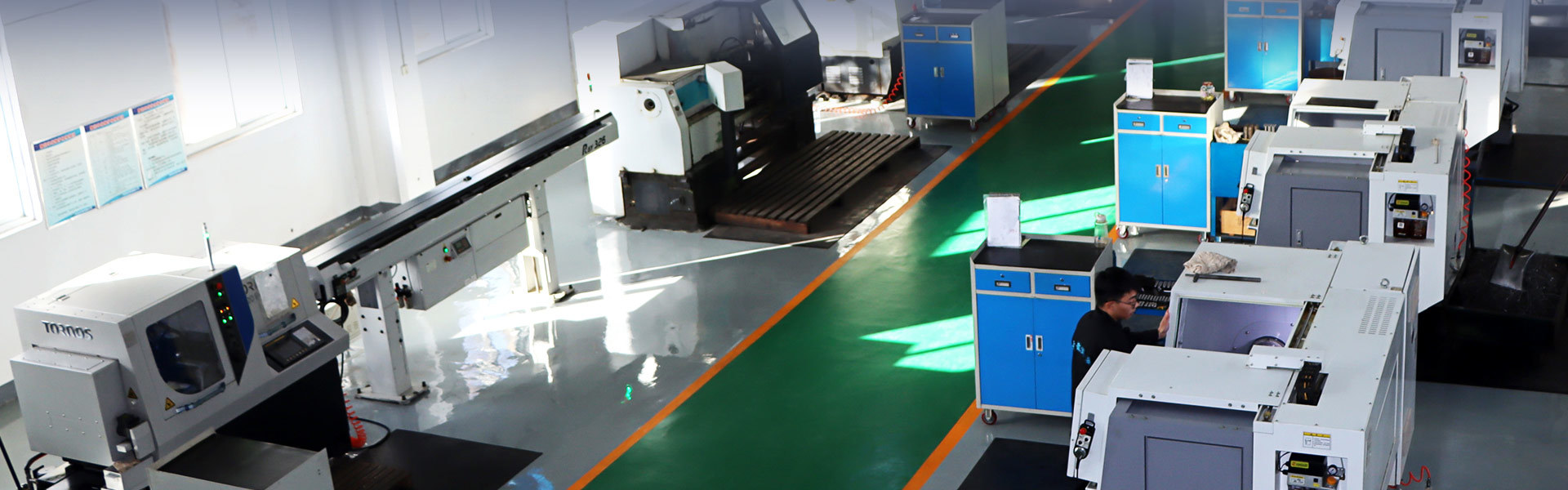

1. As shown in the figure above, it is not advisable to install at the highest point of the pipeline; change the installation position.

2. If the installation position is difficult to change, a gas collector can be installed upstream of the flowmeter to periodically vent.

A 2 The liquid to be measured is not full in the pipe.

It can be said that a non-full pipe is an extreme case of containing bubbles, where the liquid in the pipe is not full and the top contains a large amount of bubbles. If the liquid has not covered the electrodes, the measurement results will be significantly affected. This is a design error in engineering.

Figure two mainly shows the correct installation diagram of the electromagnetic flowmeter; remember, it is definitely correct.

Next page:

Real-time information

Setting sail, embarking on a new journey

2025-03-21

Golden autumn assistance warms the heart.

2024-09-30